Ukusetyenziswa kwe-SMT ye-back-end cell line kwishishini le-elektroniki le-3C

GREEN liShishini leSizwe lobuGcisa obuPhezulu elizinikele kwi-R&D kunye nokuveliswa kweendibano zombane ezizisebenzelayo kunye nokupakishwa kwe-semiconductor kunye nezixhobo zokuvavanya.

Ukukhonza iinkokeli zeshishini ezinje nge-BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, kunye ne-20+ namanye amashishini eFortune Global 500. Iqabane lakho elithembekileyo kwizisombululo zokwenziwa kwemveliso.

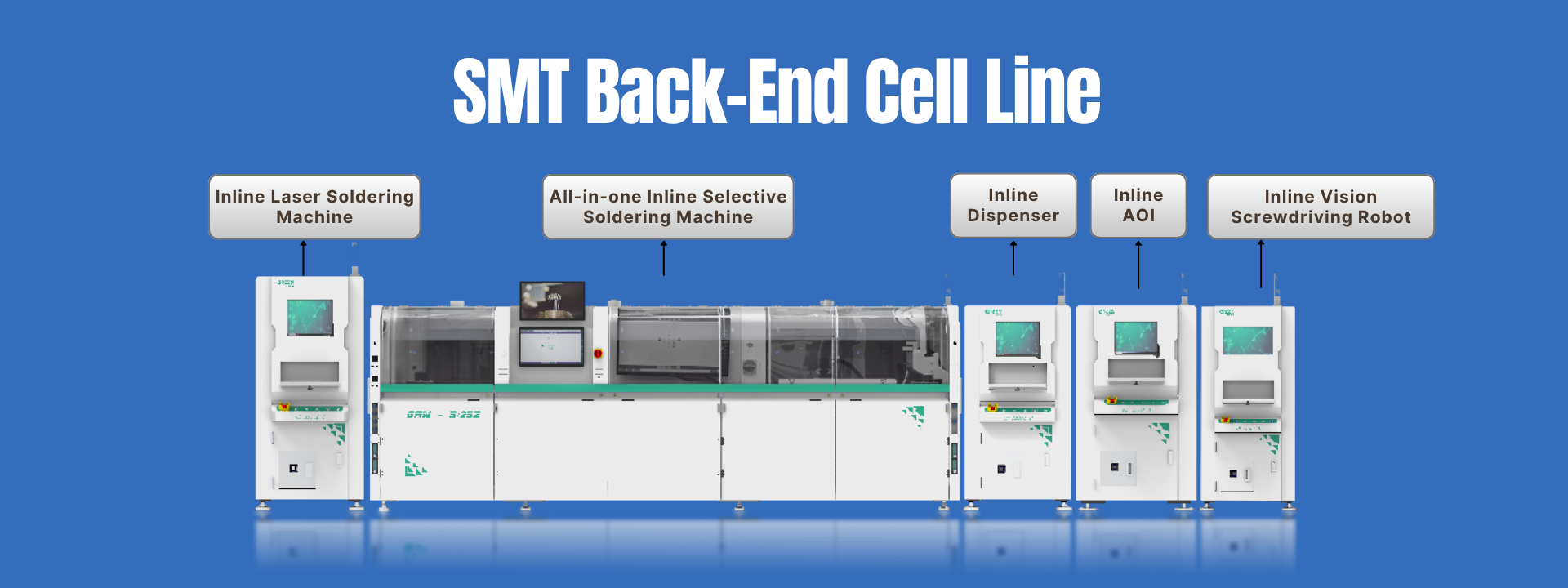

I-Surface Mount Technology (SMT) yinkqubo engundoqo kwimveliso ye-elektroniki yale mihla, ingakumbi kwishishini le-3C (ikhompyutha, unxibelelwano, i-electronics yabathengi). Iphakamisa amacandelo angenayo i-leadless / short-lead components (SMDs) ngokuthe ngqo kwi-PCB surfaces, eyenza ukuba ubuninzi obuphezulu, obuncinci, obuncinane, ukunyaniseka, kunye nokuveliswa komgangatho ophezulu.Iimigca ye-SMT isetyenziswe njani kwishishini le-elektroniki ye-3C, kunye nezixhobo eziphambili kunye neenkqubo zenkqubo kwi-SMT umva we-cell line.

□ Iimveliso ze-elektroniki ze-3C (ezinje ngee-smartphones, iitafile, iilaptops, ii-smartwatches, ii-headphones, iirutha, njl.njl.) zifuna i-miniaturization egqithisileyo, iiprofayili ezincinci, ukusebenza okuphezulu,kwaye ngokukhawuleza

Imigca ye-SMT isebenza njengendawo esembindini yemveliso eqwalasela ngokuchanekileyo ezi mfuno.

□ Ukufezekisa i-Miniaturization eBabekileyo kunye nokuKhanya:

I-SMT yenza ulungiselelo olushinyeneyo lwamacandelo amancinci (umzekelo, 0201, 01005, okanye izixhasi ezincinci/i-capacitors; iitshiphusi ze-BGA/CSP ezixineneyo) kwiiPCB, inciphisa kakhulu ibhodi yesekethe.

unyawo, umthamo wesixhobo esipheleleyo, kunye nobunzima-isixhobo esibalulekileyo sokuvumela izixhobo eziphathwayo njengee-smartphones.

□ Ukunika amandla uMdibaniso woXinano oluPhezulu kunye nokuSebenza okuPhezulu:

Iimveliso zale mihla ze-3C zifuna imisebenzi entsonkothileyo, efuna ukuxinana okuphezulu koqhagamshelwano (HDI) PCBs kunye neendlela ezininzi ezintsonkothileyo. Ukuchaneka kwezakhono zokubekwa kwe-SMT zenza i

isiseko soqhagamshelo oluthembekileyo lweengcingo ezinoxinano oluphezulu kunye neetshiphusi eziphambili (umzekelo, iiprosesa, iimodyuli zememori, iiyunithi zeRF), ukuqinisekisa ukusebenza kwemveliso ngeyona ndlela.

□ Ukomeleza iMveliso eSebenzayo kunye nokuNcitshiswa kweendleko:

Imigca ye-SMT ihambisa i-automation ephezulu (ukushicilela, ukubekwa, ukuhamba kwakhona, ukuhlolwa), i-ultra-fast throughput (umzekelo, amazinga okubeka adlula i-100,000 CPH), kunye nongenelelo oluncinci lwezandla. Oku

iqinisekisa ukungaguquguquki okukhethekileyo, amazinga aphezulu esivuno, kwaye ithoba kakhulu iindleko zeyunithi nganye kwimveliso yobuninzi-ihambelana ngokugqibeleleyo ne-3C products'demands ngexesha elikhawulezayo ukuya kwimarike kunye

amaxabiso okhuphiswano.

□ Ukuqinisekisa ukuthembeka kunye noMgangatho weMveliso:

Iinkqubo ze-SMT eziphucukileyo-kubandakanya ukuchaneka koshicilelo, ukubekwa ngokuchaneka okuphezulu, iprofayili elawulwayo, kunye nokuhlolwa okungqongqo kwe-inline-isiqinisekiso sokungaguquguquki kwe-solder kunye

ukuthembeka. Oku kunciphisa kakhulu iziphene ezinje ngokubanda kwamalungu, ukubopha ibhulorho, kunye nokungalungelelanisi kakuhle kwecandelo, ukuhlangabezana neemfuno ezingqongqo zozinzo lwemveliso ye-3C ngokungqongqo.

iindawo ezisingqongileyo (umzekelo, ukungcangcazela, ukukhwela ibhayisekile eshushu).

□ Ukuziqhelanisa nokuPhindwa kweMveliso eKhawulezayo:

Ukuhlanganiswa kwemigaqo yeFlexible Manufacturing System (FMS) yenza ukuba imigca ye-SMT itshintshe ngokukhawuleza phakathi kweemodeli zemveliso, iphendule ngokuguquguqukayo ngokukhawuleza.

iimfuno zemarike 3C.

I-Laser Soldering

Ivumela ukuchaneka kwe-solder elawulwa yiqondo lobushushu ukunqanda umonakalo kumalungu e-thermosensitive. Isebenzisa ukusetyenzwa kwe-non-contact okuphelisa uxinzelelo lomatshini, ukuphepha ukufuduswa kwecandelo okanye i-PCB deformation-elungiselelwe indawo egobileyo / engaqhelekanga.

Ukunyuswa kwamaza okukhethiweyo

IiPCB ezinabantu abaninzi zingena kwi-oven yokufudumeza, apho iprofayili yokushisa elawulwa ngokuchanekileyo (i-preheating, i-soaking, i-reflow, ukupholisa) inyibilika i-solder paste. Oku kuvumela ukumanzisa iipads kunye necandelo elikhokelayo, ukwenza iibhondi zesinyithi ezithembekileyo (amalungu e-solder), kulandele ukuqina xa kupholiswa. Ulawulo lwe-curve yobushushu lubaluleke kakhulu kumgangatho we-weld kunye nokuthembeka kwexesha elide.

I-Automatic Full-Speed-High-Speed In-Line Dispensation

IiPCB ezinabantu abaninzi zingena kwi-oven yokufudumeza, apho iprofayili yokushisa elawulwa ngokuchanekileyo (i-preheating, i-soaking, i-reflow, ukupholisa) inyibilika i-solder paste. Oku kuvumela ukumanzisa iipads kunye necandelo elikhokelayo, ukwenza iibhondi zesinyithi ezithembekileyo (amalungu e-solder), kulandele ukuqina xa kupholiswa. Ulawulo lwe-curve yobushushu lubaluleke kakhulu kumgangatho we-weld kunye nokuthembeka kwexesha elide.

Umatshini we-AOI

Uhlolo lwe-AOI yasemva kokuhanjiswa kwakhona:

Emva kwe-reflow soldering, iinkqubo ze-AOI (Automated Optical Inspection) zisebenzisa iikhamera ezinesisombululo esiphezulu kunye nesofthiwe yokucubungula imifanekiso ukuze ihlole ngokuzenzekelayo umgangatho odibeneyo we-solder kwii-PCB.

Oku kuquka ukufumanisa iziphene ezifana nezi:Iziphene zeSolder: Ayonelanga/i-solder egqithisileyo, amalungu abandayo, ibhulorho.Iziphene zecandelo: Ukulungelelaniswa kakuhle, izinto ezingekhoyo, iinxalenye ezingalunganga, i-polarity ebuyiselweyo, ilitye lengcwaba.

Njengeyona ndawo ibalulekileyo yokulawula umgangatho kwimigca ye-SMT, i-AOI iqinisekisa imfezeko yokwenziwa kwemveliso.

Umbono-oKhokelwe nguMshini wokuKhwela ongaphakathi

Ngaphakathi kwemigca ye-SMT (i-Surface Mount Technology), le nkqubo isebenza njengesixhobo se-post-assembly, ukukhusela amacandelo amakhulu okanye izinto zesakhiwo kwii-PCB-ezifana nezitshixo zokushisa, izixhumi, izibiyeli zezindlu, njl.