Isikhululo esiNye esithe nkqo eBlue Light Laser Solder Automatic Laser Soldering Machine

Iinkcukacha

| Igama lebrand | LUHLAZA |

| Umzekelo | UMTHETHO501 |

| Igama lemveliso | Umatshini wokuSonga ngeLaser |

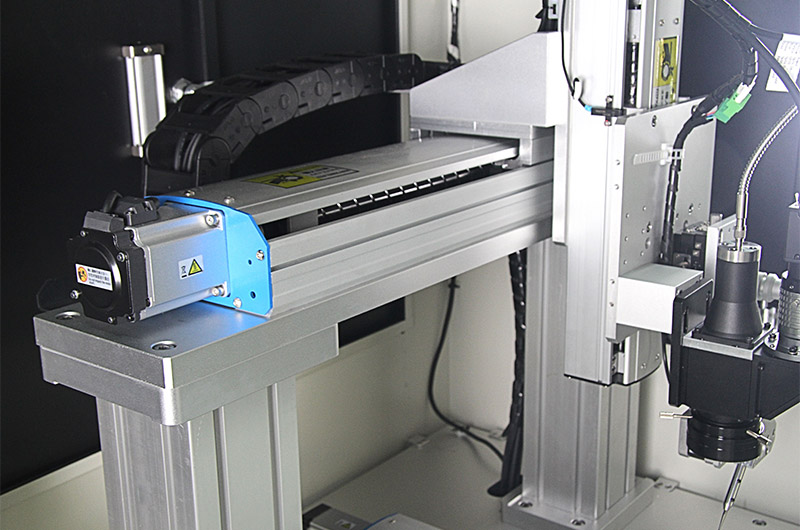

| Uhambo lweQonga | X=400, Y=400, Z=150mm |

| Uluhlu lokuLungiselela | 350*350mm |

| Laser Wavelength | 445mm |

| Ubuninzi bamandla oPhumo lweLaser | 40W |

| Ukuphindaphinda Ukuchaneka | ±0.02mm |

| Imowudi yeDive | I-AC220V 10A 50-60HZ |

| Uhlobo | Umatshini wokuSoda |

| Uhlobo lweLaser | Blue light semiconductor laser |

| Uhlobo lwe-weld | I-laser tin wire |

| Ubunzima (KG) | 200KG |

| Amanqaku okuThengisa aPhambili | Iyazenzekela |

| Indawo yeMvelaphi | eTshayina |

| Iwaranti yamacandelo angundoqo | 1 Unyaka |

| Iwaranti | 1 Unyaka |

| Uhlolo lwevidiyo oluphumayo | Kubonelelwe |

| Ingxelo yoVavanyo koomatshini | Kubonelelwe |

| Indawo yokubonisa | Akukho nanye |

| Uhlobo lweNtengiso | Imveliso eqhelekileyo |

| Imeko | Entsha |

| Amacandelo Angundoqo | IMoto, ikhompyuter yeShishini, isiKhokelo esichanekileyo, iKhamera, iScrew |

| Amashishini asebenzayo | Iivenkile zokulungisa oomatshini, iplanti yokuvelisa, enye, iShishini loNxibelelwano, i-3C Consumer Electronics Industry, iShishini yeemoto, iShishini laMandla amatsha, iShishini le-LED, i-Electronics Industry |

Uphawu

GREEN LAW501 Floor uhlobo loMgangatho weBlue Light Laser Soldering Machine

1. Ukuchaneka okuphezulu: indawo yokukhanya inokufikelela kwinqanaba le-micron, kwaye ixesha lokucubungula linokulawulwa yiprogram, okwenza ukuchaneka kuphezulu kakhulu kunenkqubo ye-solder yendabuko.

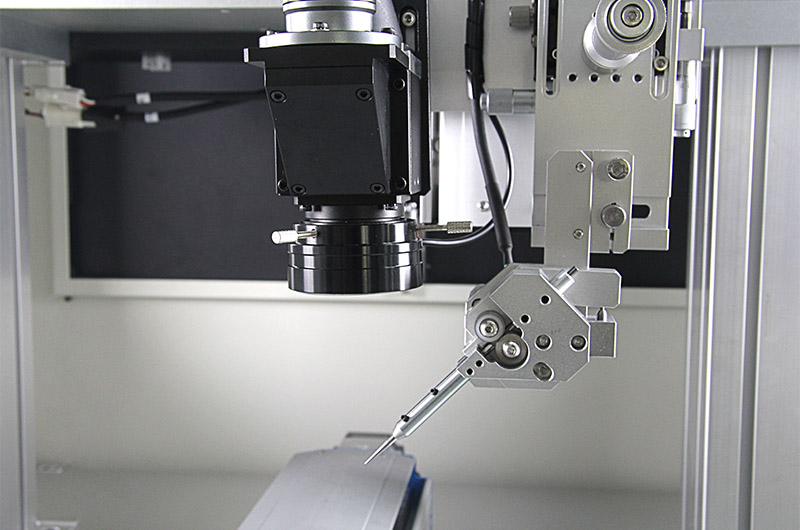

2. Ukusingathwa koqhagamshelwano: inkqubo ye-soldering inokugqitywa ngaphandle kokuqhagamshelana ngokuthe ngqo kwendawo, ngoko akukho xinzelelo olubangelwa ukudibanisa i-welding.

3. Iimfuno zendawo yokusebenza encinci: i-laser encinci ye-laser ithatha indawo yentsimbi ye-soldering, kunye nokulungiswa ngokuchanekileyo kwenziwa kwakhona xa kukho ezinye iziphazamiso kumphezulu we-workpiece.

4. Indawo encinci yokusebenza: ukufudumeza kwendawo, indawo echaphazelekayo yokushisa incinci.

5. Inkqubo yokusebenza ikhuselekile: akukho sisongelo se-electrostatic ngexesha lokucubungula.

6. Inkqubo yokusebenza icocekile kwaye inoqoqosho: i-laser processing consumables, akukho nkunkuma eyenziwa ngexesha lokucubungula.

I-7.ukusebenza okulula kunye nokugcinwa: ukusebenza kwe-laser soldering kulula, ukulungiswa kwentloko ye-laser kulula.

8. Ubomi benkonzo: Ubomi be-laser bunokusetyenziselwa ubuncinane iiyure ze-10,000, kunye nobomi obude kunye nokusebenza okuzinzile.

Umsebenzi

I-soldering ezenzekelayo yezikhonkwane ekuphunyezweni okuhlukeneyo kweebhodi. I-laser soldering ingasetyenziselwa ezona zixhobo zininzi ezahlukeneyo. Iirobhothi ezithengisayo zilahla i-laser ekwenziwa uqhagamshelo kwi-solder ngexesha elifutshane.

Irobhothi yokuzenzela (i-automatic programmer)

I-Nomenclature ekhethekileyo: irobhothi yeprogram ezenzekelayo, isitshisi esizenzekelayo, umdwelisi okrelekrele, isixhobo sokwenza inkqubo esizenzekelayo ngokupheleleyo, isitshisi esizenzekelayo esizenzekelayo, ezi magama zikhethekileyo ngokwenene zizixhobo ezifanayo (endaweni yokucwangcisa i-chip yezandla Yomdwelisi wenkqubo ozenzekelayo, ezi zilandelayo ezidityanisiweyo ezaziwa ngokuba ngumdwelisi we-chip ozenzekelayo ngokupheleleyo)

I-Nomenclature ekhethekileyo: irobhothi yeprogram ezenzekelayo, isitshisi esizenzekelayo, umdwelisi okrelekrele, isixhobo esizenzekelayo esizenzekelayo, isitshisi esizenzekelayo esizenzekelayo, olu luhlu lwamagama lukhethekileyo ngokwenene zizixhobo ezifanayo (endaweni yeprogram ye-chip yezandla Yomdwelisi wenkqubo ozenzekelayo, ezi zilandelayo ezidityanisiweyo ezaziwa ngokuba yi-chip ngokuzenzekela ngokupheleleyo umdwelisi)

Umphathi weSoldering (kwincam yentsimbi)

Ukubonwa kwemeko yokusebenza kwerobhothi, kubandakanywa ulungelelwaniso kwindawo nganye, izixhobo zokubala ezahlukeneyo, iqondo lobushushu, njl.

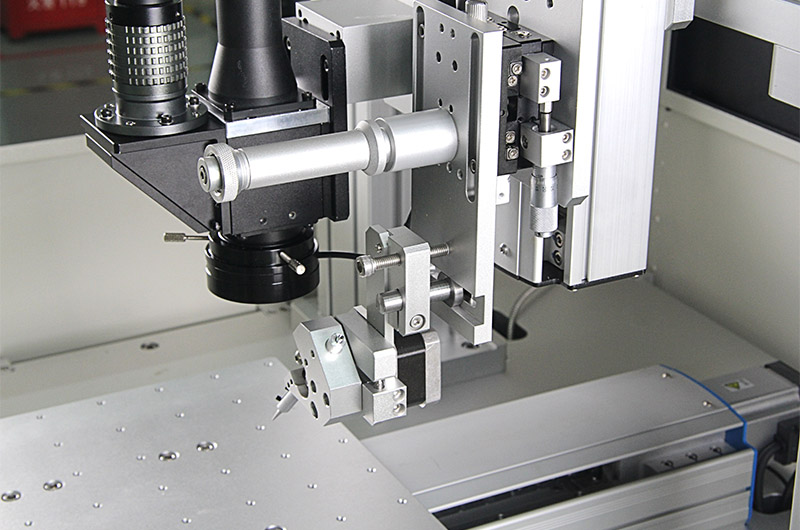

Onke amaxabiso okulungisa nge-3-axis tip position correction mechanism, amaxabiso okulinganisa amaqondo obushushu yi-UNI-TESTER, amaxabiso okuzilungisa okuzenzekelayo, ukuxhathisa i-tip grounding, kunye ne-voltage evuzayo irekhodwa.

Ukurekhoda kwevidiyo kunye nedatha ngexesha le-soldering kwandisa ukulandeleka

Ulawulo lothotho ngokufunda iikhowudi ze-2D

Ulawulo lwenkqubo yehlabathi lunokwenzeka ngokwabelana ngedatha efunyenweyo