Umatshini wokuSolisa weDuplex Laser

IParameter yesixhobo

| into | ixabiso |

| Uhlobo | Umatshini wokuSoda |

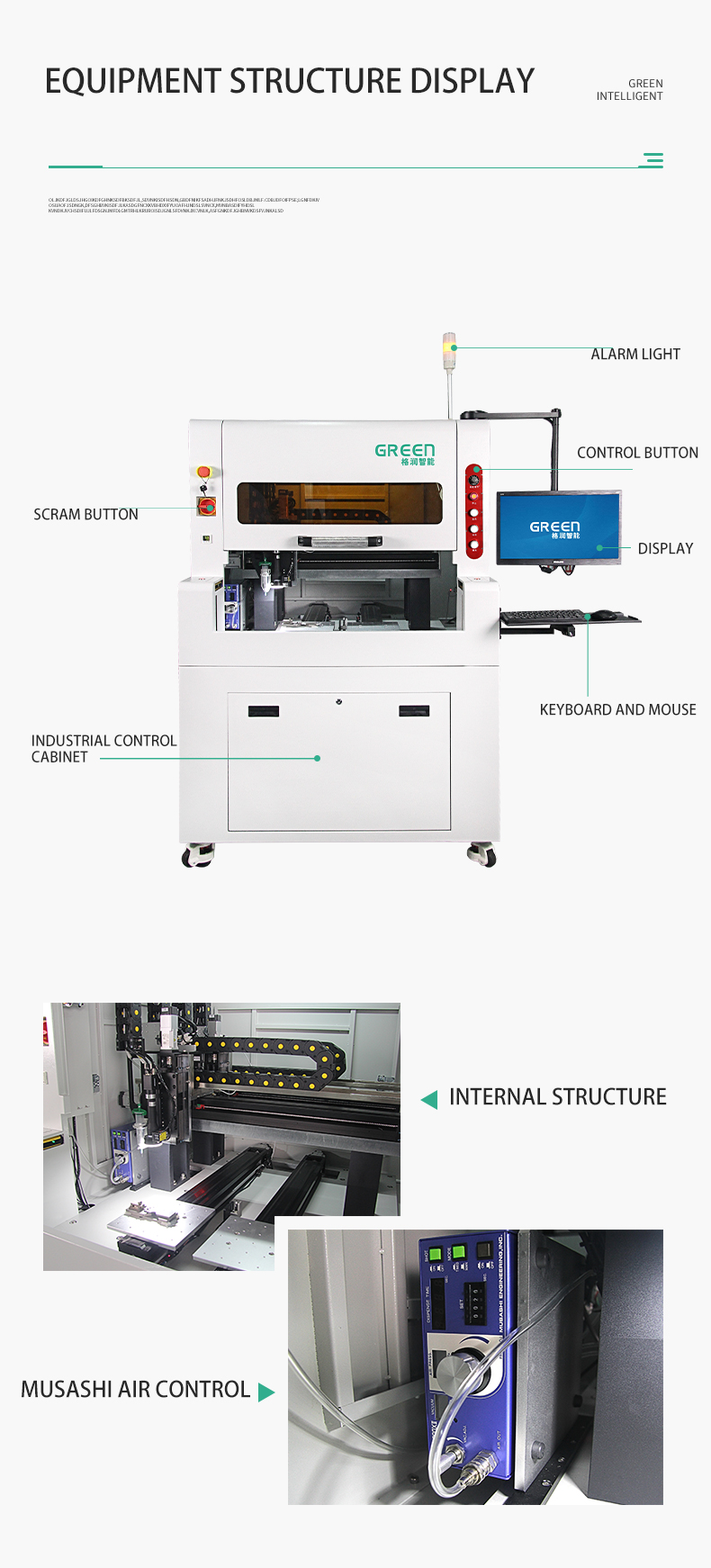

| Amacandelo Angundoqo | IMoto, ikhompyuter yeShishini, iLaser, iCCD, iNkqubo yeMES, isiKhokelo esichanekileyo, iPC yoShishino, iServo motor |

| Igama lebrand | Luhlaza |

| Ireyithwe uMjikelo woMsebenzi | 50-60HZ |

| Umthamo olinganiselweyo | 2.0KW |

| I-Voltage | 220V |

| Okwangoku | 10A |

| Ukusetyenziswa | i-soldering wire |

| Amanqaku okuThengisa aPhambili | Inkqubo ye-MES |

| Ubunzima (KG) | 200KG |

| Amandla eLaser | 200W |

| Ubude beLaser | 915nm |

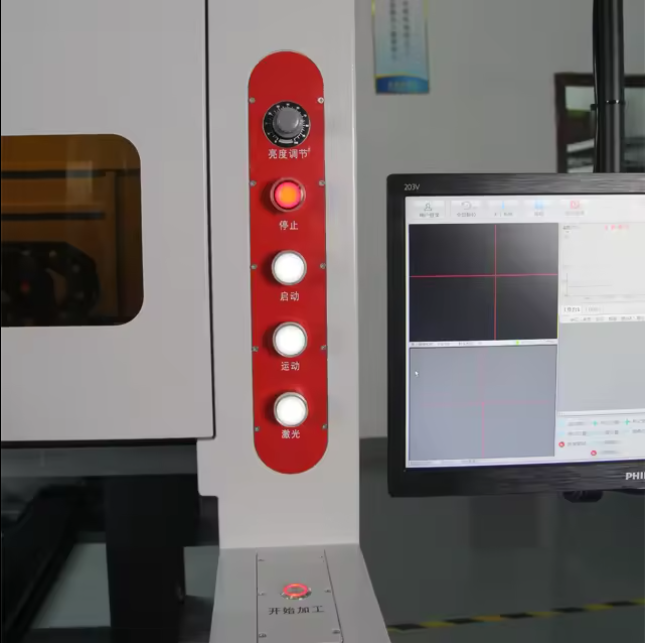

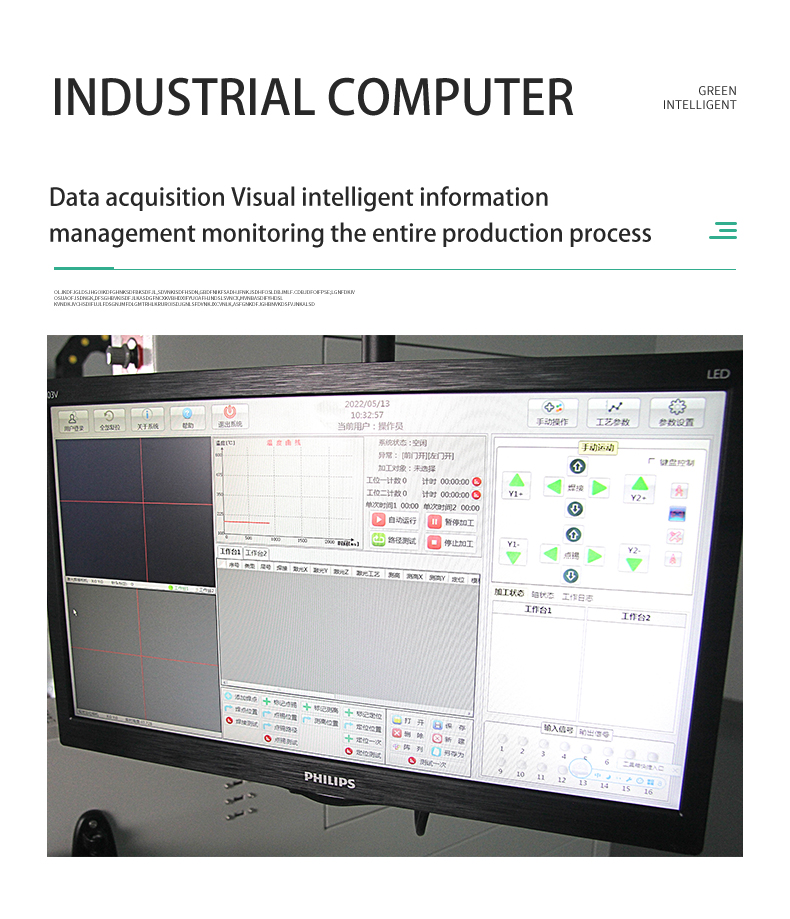

| Imo yokulawula | I-Microcomputer + iPC yokulungisa umfanekiso |

| Inkqubo yendawo yombono | ±0.01mm |

| Uluhlu lokuqhubekekisa | 300 * 300Machinable ≤ 0.15pitch |

| Tin endleleni | Intlama yesolder enechaphaza yetoti esele yenziwe, ungazikhethela |

| Uhlobo lwe-weld | I-Laser tin ucingo |

| Ukunikezwa Amandla | I-AC220V 10A 50-60Hz |

| Uxinzelelo lomoya lokufaka | 0.4~0.7MPa |

| Amandla enkqubo | 100(900 amanqaku/ifayile yenkqubo) |

| Amandla onke | 1.5KW |

| Ubume bangaphandle(L*W*H) | 1200*1200*1700(mm) |

Iimpawu zesixhobo

1. Ixhotyiswe ngenkqubo yokubonelela ngee-solder ezintandathu.

2. Inkqubo yokulinganisa ubushushu be-coaxial, i-curve yokulawula ubushushu bexesha langempela.

3. Kwi-welding ye-FPC kunye ne-PCB, i-patch ayikho i-temperature-resistant components, kwaye i-thermal components i-welded.

4. Iinzuzo ezibalaseleyo, ukusebenza kakuhle okuphezulu kunye nokusebenza kakuhle.

Iinkcukacha

Indawo yosetyenziso

Ushishino lonxibelelwano

Ishishini lomkhosi Iimoto ze-elektroniki Oomatshini bonyango I-Aerospace

Iimveliso ze-elektroniki