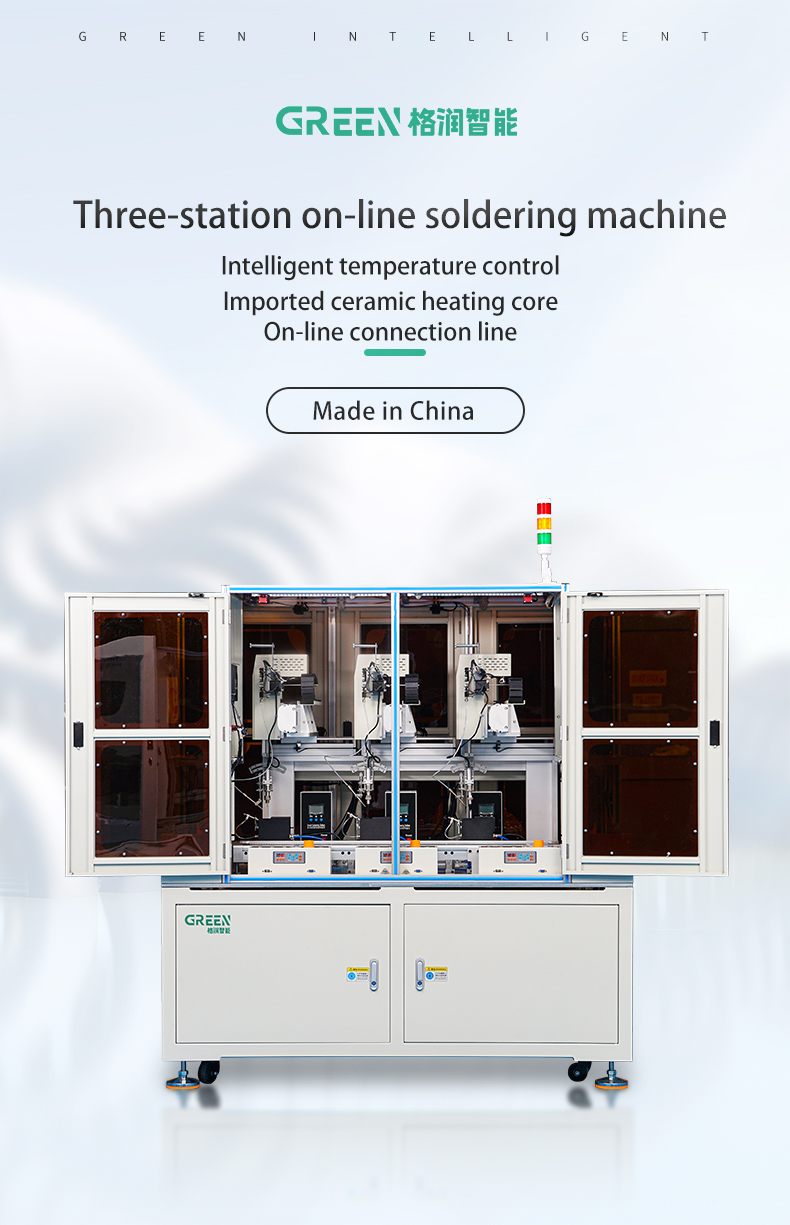

IMveliso ePhakamileyo ngokuSebenzayo ngokuSebenzayo koomatshini bokuSoda kwisikhululo sesithathu se-On-line

IParameter yesixhobo

| Umzekelo | GR-OH05 |

| Amanqaku okuThengisa aPhambili | Iyazenzekela |

| Ubunzima (KG) | 1200KG |

| Uhlobo | Umatshini wokuSoda |

| Igama lebrand | Luhlaza |

| Ireyithwe uMjikelo woMsebenzi | Iiyure ezingama-24 ngokuqhubekayo |

| Umthamo olinganiselweyo | Ukhetho |

| I-Voltage | 220V |

| Okwangoku | 50HZ |

| Imilinganiselo | L1700mm*W900mm*H1835mm |

| Sebenzisa | PCB |

| Solder stroke | 100*200*100(iyunithi: mm) |

| Isantya sentshukumo | Umgca we-XY (0~ 800mm,s) Umgca we-Z (0 ~ 300mm,s) |

| Rukukwazi ukuphila | ±0.02 mm |

| umthwalo | 0.4~0.7MPa |

| Amandla enkqubo | Ukuhambisa umthwalo womgca 10KG |

| Umlawuli wobushushu | 150W,200W,400W ukukhetha |

| Uluhlu lobushushu | 0 ~ 450℃ |

| Uluhlu lobushushu be-alarm | Uluhlu lobushushu be-alarm |

| Ixesha lokufudumeza | 0~9.9s |

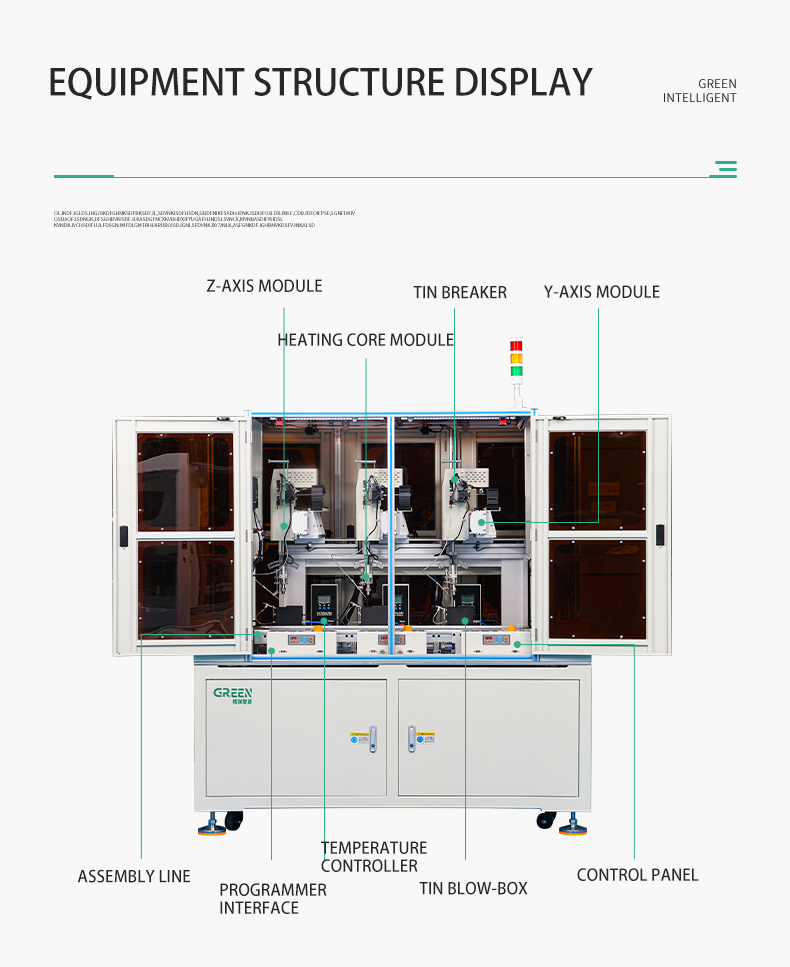

Iimpawu zesixhobo

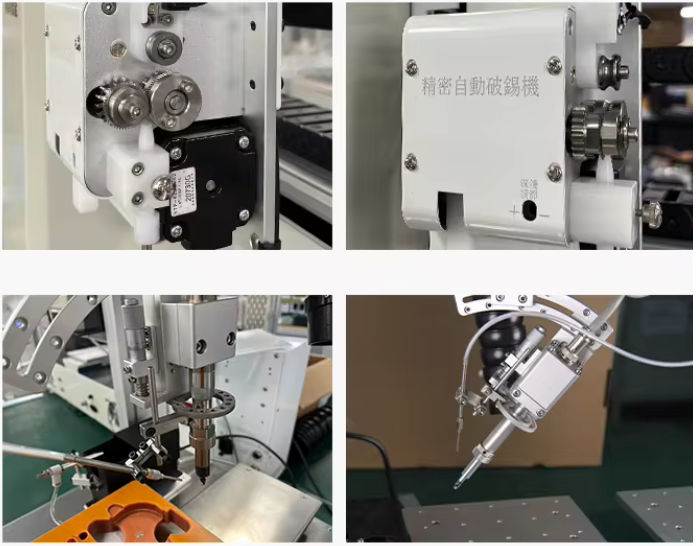

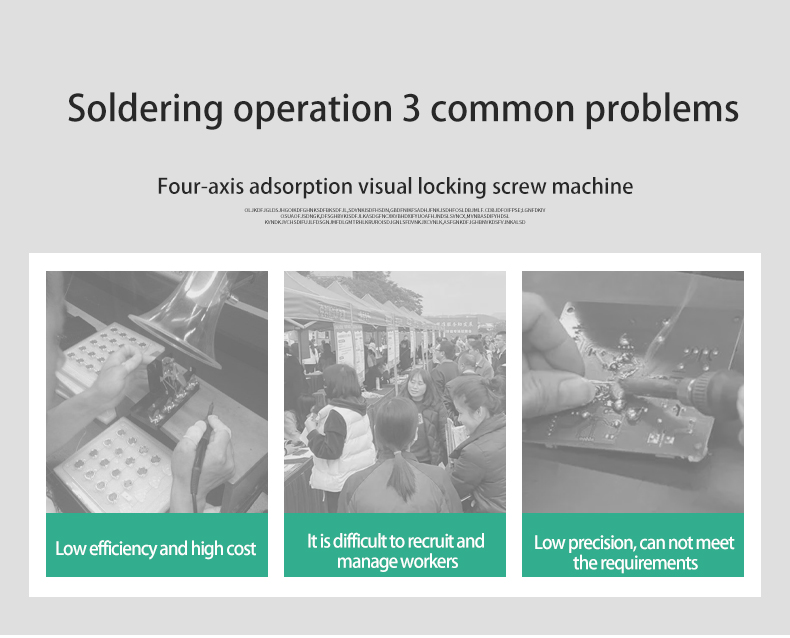

1.Iindlela zokuthambisa eziguquguqukayo, kunye ne-welding yendawo, i-welding yokutsala (i-welding yokutsala) kunye neminye imisebenzi

I-2.Isixhobo sinokugcina iifayile ze-150 zokucubungula, amanqaku eprogram ye-1500 kwiqela ngalinye

3.I-Solder jitter function, ukuvula lo msebenzi xa i-welding inokwenza i-welding ikhawuleze, isebenze ngakumbi kumalungu amakhulu e-solder.

4. Umzila odibeneyo we-solder uyabonakala, ukwenzela ukuba umqhubi unokuqonda inkqubela ye-solder kunye nabasebenzi bobunjineli banokuyilungisa ngokulula.

5. Iprogram yomsebenzi wokubhala isixhobo inokukopishwa ukusuka kwindawo ukuya kwindawo kunye nebhloko ukuya kwibhloko, ukunciphisa ixesha lokubhala inkqubo kwaye kulula ukuyifunda.

6. Isixhobo sinomsebenzi wokucoca ngokuzenzekelayo, oqinisekisa ngokufanelekileyo umgangatho wokucutshungulwa kwe-solder kunye nokwandisa ubomi benkonzo ye-tip ye-iron soldering.

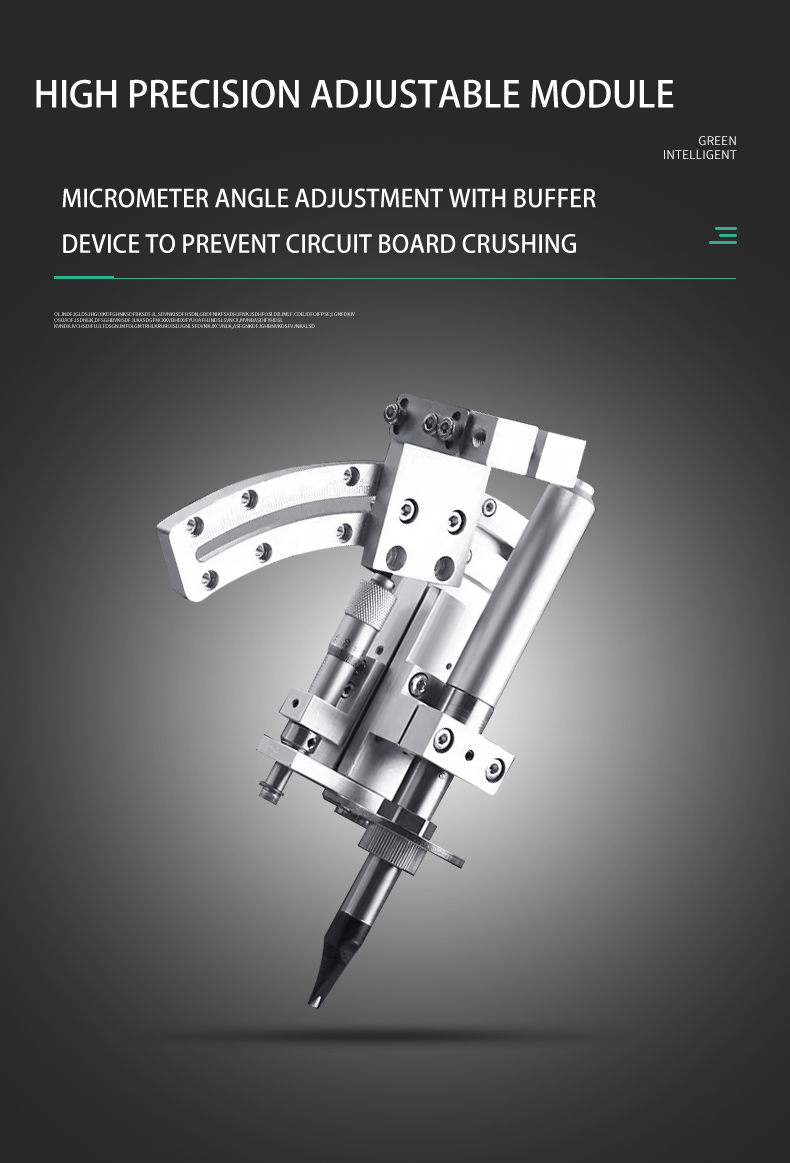

7. Ukuchaneka ukunyathela i-motor drive kunye ne-algorithm yokulawula intshukumo ephuculweyo yamkelwa ukuze iphucule ngokufanelekileyo ukuchaneka kokumiswa kunye nokuphindaphinda ukuchaneka.

8. Umsebenzi otshintshanayo wesikhululo esiphindwe kabini, elinye icala ngumsebenzi we-welding, elinye icala linokubekwa imveliso, liphucule ngempumelelo imveliso.

Uluhlu lweSicelo

Ifowuni ephathwayo, ikhompyuter, isekethe edibeneyo, ithebhulethi, imboni yeemoto zedijithali, indibano yebhetri, isandisi-lizwi, ibhodi yePCB, indibano ye-semiconductor microelectronics, imodyuli yemodyuli yekhamera.

Ukupakisha kunye nokuhanjiswa