Isicelo kwishishini leSemiconductor

GREEN liShishini leSizwe lobuGcisa obuPhezulu elizinikele kwi-R&D kunye nokuveliswa kweendibano zombane ezizisebenzelayo kunye nokupakishwa kwe-semiconductor kunye nezixhobo zokuvavanya. Ukukhonza iinkokeli zeshishini ezinje nge-BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, kunye ne-20+ namanye amashishini eFortune Global 500. Iqabane lakho elithembekileyo kwizisombululo eziphambili zokuvelisa.

Oomatshini bokudibanisa benza ukuba i-micro-interconnects kunye needamitha zocingo, iqinisekise ingqibelelo yesignali; i-formic acid vacuum soldering yenza amajoyina athembekileyo phantsi komxholo we-oksijeni <10ppm, ukuthintela ukungaphumeleli kwe-oxidation kwipakethe ephezulu yoxinaniso; I-AOI ibamba iziphene zenqanaba le-micron. Le synergy iqinisekisa> 99.95% isivuno esiphezulu sokupakisha, ukuhlangabezana neemfuno zokuvavanya ngokugqithiseleyo kwee-chips ze-5G / AI.

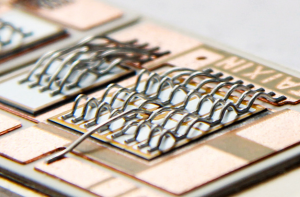

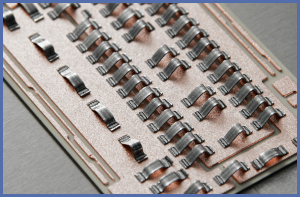

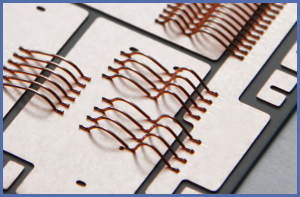

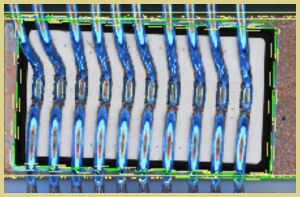

Ultrasonic Wire Bonder

Iyakwazi ukudibanisa i-100 μm-500 μm i-aluminium yocingo, i-200 μm-500 μm ucingo lobhedu, iiribhoni ze-aluminium ukuya kwi-2000 μm ububanzi kunye ne-300 μm ubukhulu, kunye neerebhoni zobhedu.

Uluhlu lokuhamba: 300 mm × 300 mm, 300 mm × 800 mm (customizable), kunye nokuphindaphinda < ± 3 μm

Uluhlu lokuhamba: 100 mm × 100 mm, kunye nokuphindaphinda < ± 3 μm

Yintoni iTekhnoloji ye-Wire Bonding?

I-wire bonding yindlela yokudibanisa i-microelectronic esetyenziselwa ukudibanisa izixhobo ze-semiconductor kwipakethe okanye i-substrates. Njengenye yetekhnoloji ebaluleke kakhulu kwishishini le-semiconductor, ivumela ukuhlangana kwe-chip kunye neesekethe zangaphandle kwizixhobo zombane.

Izixhobo zocingo zoBonding

1. IAluminiyam (Al)

Ukwenziwa kombane okugqwesileyo xa kuthelekiswa negolide, kungabizi mali ininzi

2. Ubhedu (Cu)

I-25% ephezulu yombane/i-thermal conductivity kune-Au

3. Igolide (Au)

Eyona conductivity ilungileyo, ukumelana nokugqwala, kunye nokuthembeka kwebhondi

4. Isilivere (Ag)

Eyona conductivity iphezulu phakathi kwesinyithi

Ucingo lweAluminiyam

Iribhoni yeAluminiyam

ucingo lobhedu

Iribhoni yobhedu

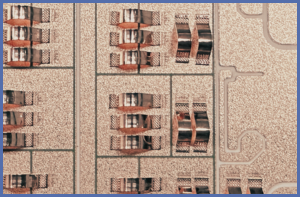

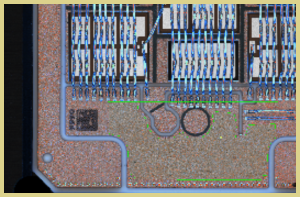

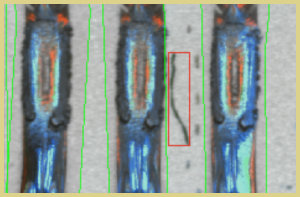

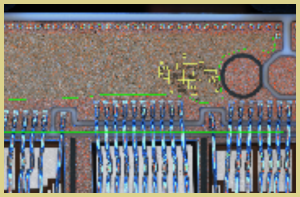

ISemiconductor Die Bonding & Wire Bonding i-AOI

Isebenzisa ikhamera yoshishino ye-25-megapixel ukukhangela i-Die attach kunye neziphene zokubopha ucingo kwiimveliso ezinjenge-ICs, IGBTs, MOSFETs, kunye neefreyimu ezikhokelayo, ukufikelela kwinqanaba lokufumanisa isiphene ngaphezu kwe-99.9%.

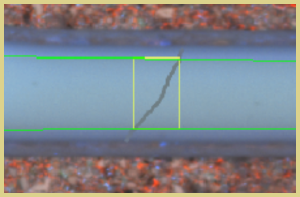

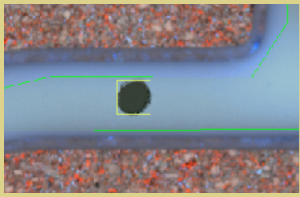

Amatyala oHlolo

Iyakwazi ukujonga ukuphakama kwetshiphu kunye nokuthe tyaba, i-chip offset, i-tilt, kunye ne-chip; ibhola ye-solder engabambeleli kunye ne-solder joint detachment; i-wire bonding iziphene kubandakanywa ukuphakama okugqithisiweyo okanye okunganelanga, ukuwa kwe-loop, iingcingo eziqhekekileyo, iingcingo ezilahlekileyo, ukudibanisa ucingo, ukugoba ucingo, ukunqumla i-loop, kunye nobude bomsila obuninzi; ukuncamathela okunganeleyo; kunye ne-metal splatter.

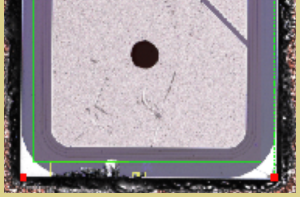

Ibhola yeSolder/ Intsalela

Chip Scratch

Ukubekwa kweChip, iDimension, iTilt Meas

Ungcoliseko lweChip / Izinto zangaphandle

Chip Chipping

Iintanda zeCeramic

Ungcoliseko lweCeramic Trench

I-AMB Oxidation

Kwi-Oveni yeFormic Acid Reflow engaphakathi

1. Elona qondo lobushushu liphezulu ≥ 450°C, ubuncinane bomgangatho wevacuum <5 Pa

2. Ixhasa i-asidi ye-formic kunye ne-nitrogen process environments

3. Inqanaba elingenanto lendawo enye ≦ 1%, ireyithi engenanto iyonke ≦ 2%

4. Ukupholisa kwamanzi + ukupholisa i-nitrogen, exhotywe ngenkqubo yokupholisa amanzi kunye nokupholisa ukudibanisa

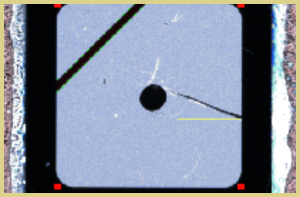

I-IGBT Power Semiconductor

Amazinga agqithisileyo okuvalwa kwe-IGBT ekuthengiseni anokubangela ukungaphumeleli kwe-chain-reaction kubandakanya ukubaleka kwe-thermal, ukuqhekeka koomatshini, kunye nokuthotywa kokusebenza kombane. Ukunciphisa amazinga e-void ukuya kwi-≤1% kwandisa kakhulu ukuthembeka kwesixhobo kunye nokusebenza kakuhle kwamandla.

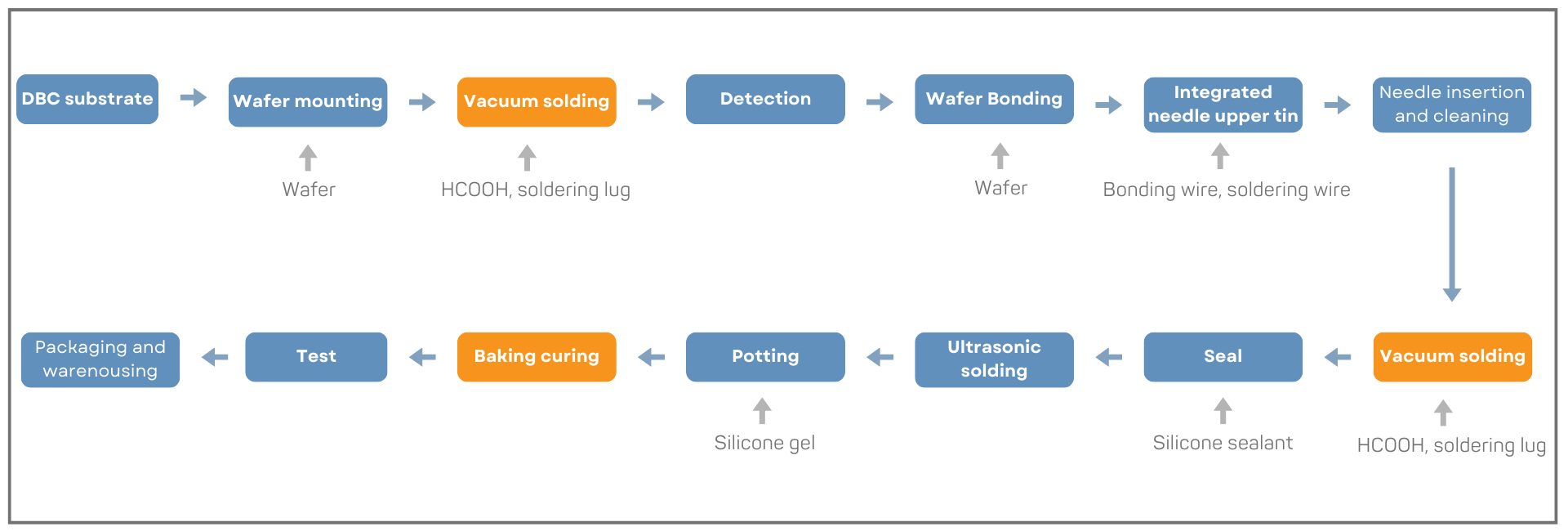

Itshati yenkqubo yoMveliso ye-IGBT